ASTM F436 Washer

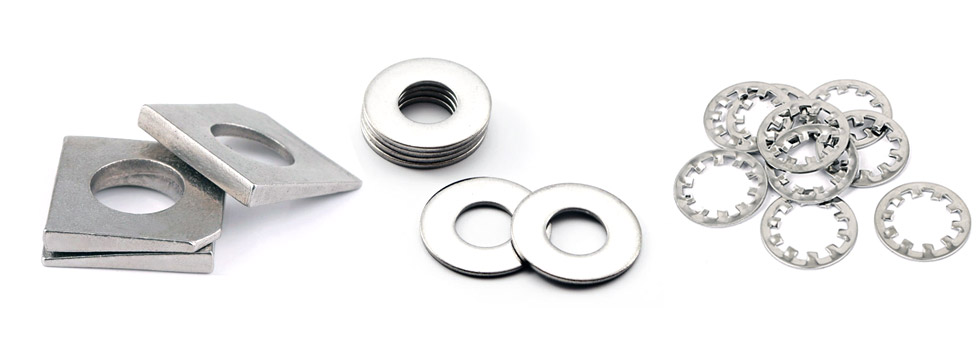

ASTM F436 Flat Washers, ASTM F436 Plain Washers, ASTM F436 Bolt Washers, ASTM F436 Slot Washer, ASTM F436 Star Washers, ASTM F436 Spring Washers, ASTM F436 Lock Washers, ASTM F436 Square Washer, ASTM F436 Punched Washer, ASTM F436 Countersunk Washers, ASTM F436 Tab Washers Manufacturers in India.

Ubique Alloys Pvt. Ltd is a distinguished manufacturer of ASTM F436 Washers, which is non-hardenable by heat treatment and can only be hardened by cold working. However, the proven ability of ASTM F436 Flat Washers to combat corrosion has widened its use considerably and is now being used for many other industrial applications. Tougher than stainless with a long stringy chip, the use of chip breakers in ASTM F436 Lock Washers is recommended. ASTM F436 Sealing Washers is used in Paper and pulp equipment, Chemical and petrochemical processing, Food processing, etc. ASTM F436 Split Washers should be annealed at 1900 Degree F / 2000 Degree F (1040 Degree C / 1095 Degree C) and water quenched. ASTM F436 Slot Washers is also used in Absorber towers, Boilers, Condenser tubes, Fittings, Heat exchangers, Outlet and inlet ductwork, etc. Work hardening in ASTM F436 Machine Washers is accentuated by the partial transformation of the austenite phase of the material to hard martensitic.

ASTM F436 Star Washers is also used in industries producing paper and pulp, and as condensers in power stations using fossil and nuclear fuels. These ASTM F436 Wire Spring Washers are more resistant to atmospheric and other mild types of corrosion than the stainless steels. ASTM F436 Flat Spring Washers is as well used in engineering and shipbuilding, chemical & Fertilizer production, for onshore & offshore industries, surgical instruments, fasteners, etc.

ASTM F436 Washers Specification

| Grade | ASTM F436 |

| Dimension | ASME B18.2.1, B18.3 |

| Coatings | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Types | Star Washer, Flat Washer, Lock Washer, Slot Washer, Machine Washer, Sealing Washer, Split Washer, Dome Tooth Washer, Countersunk Washer, Tab Washers, Spherical Washer, Square Washer, Spring Washer, Round Washers, Square Washers etc |

ASTM F436 Property Class

| For Bolts & Screws | A2-70, A2-80, A4-70, A4-80, F593C, F593D, F593G, F593H |

| For Nuts | A2-70, A2-80, A4-70, A4-80, F594C, F594D, F594G, F594H, A2-035, A4-040 |

| For SHCS | F837B, F837C, F837E, F837 |

| For Threaded Rods | A2-70, A2-80, A4-70, A4-80, F593C, F593D, F593G, F593H, B8, B8M CL1 & CL2 |

ASTM F436 Equivalent Grade

| STANDARD | Specification |

| ASTM F436 | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

ASTM F436 Washers Material Specification

| Stainless Steel | AISI 302, 304, 304L,316, 316L, 310, 317, 317L, 321, 347, 410, 420,904L etc. |

| Duplex & Super Duplex Steel | ASTM / ASME A815 UNS No. S31803, UNS No. S 32205, UNS No. S 31254, UNS No. S 31550, UNS No. S 32750, and UNS No. S 32760 |

| Carbon Steel | ASTM A307, A193 |

| Alloy Steel | ASTM / ASME A/SA 193 / 194 B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

| Nickel Alloy | ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3) |

ASTM F436 Flat Washers Dimensions

Bolt Size | USS | SAE | ||||

OD (in.) | ID (in.) | Thickness | OD (in.) | ID (in.) | Thickness | |

1/8 (#6) | 0.375 | 0.156 | .036/.065 | |||

5/32 (#8) | 0.438 | 0.188 | .036/.065 | |||

3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

7/32 (#12) | 0.562 | 0.250 | .051/.080 | |||

1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

1 5/8 | 3.750 | 1.750 | .153/.213 | |||

1 3/4 | 4.000 | 1.875 | .153/.213 | |||

1 7/8 | 4.250 | 2.000 | .153/.213 | |||

2 | 4.500 | 2.125 | .153/.213 | |||

2 1/4 | 4.750 | 2.375 | .320/.248 | |||

2 1/2 | 5.000 | 2.625 | .210/.280 | |||

2 3/4 | 5.250 | 2.875 | .228/.410S | |||

3 | 5.500 | 3.125 | .249/.327 | |||

ASTM F436 Washers Chemical Composition

| Element | Type 1 | Type 3 |

| Phosphorous, max | 0.040% | 0.040% |

| Sulfur, max | 0.050% | 0.050% |

| Silicon | – | 0.15 – 0.35% |

| Chromium | – | 0.45 – 0.65% |

| Nickel | – | 0.25 – 0.45% |

| Copper | – | 0.25 – 0.45% |

ASTM F436 Washers Mechanical Properties

| Plain Finish | Hot Dip Galvanized |

| Rockwell Hardness 38 to 45 HRC | Rockwell Hardness 26 to 45 HRC |

ASTM F436 Washer Weight Chart

| Bolt Size | B | A | C | Weight (lbs.) Per 1000 Pieces | Part Numbers | ||

| Outside Diameter | Inside Diameter | Thickness | Domestic | ||||

| Min | Max | Plain | Galvanized | ||||

| 1⁄2 | 11⁄16 | 17⁄32 | 0.097 | 0.177 | 18 | 16440 | 16441 |

| 5⁄8 | 15⁄16 | 11⁄16 | 0.122 | 0.177 | 33 | 16442 | 16443 |

| 3⁄4 | 115⁄32 | 13⁄16 | 0.122 | 0.177 | 41 | 16444 | 16445 |

| 7⁄8 | 13⁄4 | 15⁄16 | 0.136 | 0.177 | 64 | 16446 | 16447 |

| 1 | 2 | 11⁄16 | 0.136 | 0.177 | 82 | 16448 | 16449 |

| 11⁄8 | 21⁄4 | 13⁄16 | 0.136 | 0.177 | 105 | 16450 | 16451 |

| 11⁄4 | 21⁄2 | 13⁄8 | 0.136 | 0.177 | 133 | 16452 | 16453 |

| 13⁄8 | 23⁄4 | 11⁄2 | 0.136 | 0.177 | 163 | 16454 | 16455 |

| 11⁄2 | 3 | 15⁄8 | 0.136 | 0.177 | 200 | 16456 | 16457 |

| 15⁄8 | 31⁄4 | 13⁄4 | 0.178 | 0.28 | 320 | 19481* | 19482* |

| 13⁄4 | 33⁄8 | 17⁄8 | 0.178 | 0.28 | 307 | 16458 | 16459 |

| 17⁄8 | 31⁄2 | 2 | 0.178 | 0.28 | 360 | 16471* | 16472 |

| 2 | 33⁄4 | 21⁄8 | 0.178 | 0.28 | 380 | 16460 | 16461 |

| 21⁄4 | 4 | 23⁄8 | 0.24 | 0.34 | 560 | 16462 | 16463 |

| 21⁄2 | 41⁄2 | 25⁄8 | 0.24 | 0.34 | 720 | 16464 | 16465 |

| 23⁄4 | 5 | 27⁄8 | 0.24 | 0.34 | 920 | 16611 | 16612 |

| 3 | 51⁄2 | 31⁄8 | 0.24 | 0.34 | 1040 | 16613 | 16614 |

| 31⁄4 | 6 | 33⁄8 | 0.24 | 0.34 | 1350 | – | – |

| 31⁄2 | 61⁄2 | 35⁄8 | 0.24 | 0.34 | 1633 | 18490 | 18460 |

| 33⁄4 | 7 | 37⁄8 | 0.24 | 0.34 | 1880 | – | – |

| 4 | 71⁄2 | 41⁄8 | 0.24 | 0.34 | 2200 | 18461 | 18462 |

Other Types of ASTM F436 Washers

| ASTM F436 Split Washer | ASTM F436 Hex Slot Washer | ASTM F436 Lock Washer |

| ASTM F436 Nord Lock Washer | ASTM F436 Clipped Hardened Washers | ASTM F436 Rosette Washers |

| ASTM F436 Tab Washers | ASTM F436 Round Washers | ASTM F436 alleable Iron Washers |

| ASTM F436 Machine Washer | ASTM F436 Wedge Lock Washers | SUS 321 Bolt Washers |

| ASTM F436 Bearing Lock Washers | ASTM F436 Spherical Washer | ASTM F436 Finishing Washers |

| ASTM F436 Star washers | ASTM F436 Sealing Washer | ASTM F436 Flat Washer |

| ASTM F436 Bevel Washers | ASTM F436 Dome Tooth Washer | ASTM F436 Slot Washer |

| ASTM F436 Plain Washers | ASTM F436 Dock Washer | ASTM F436 Punched Washer |

| ASTM F436 Countersunk Washer | ASTM F436 Split Lock Washer | ASTM F436 Fender Washers |

Countries We Export to

Ubique Alloys Pvt. Ltd. manufactures and exports to various countries such as Saudi Arabia, Bangladesh, United States, United Arab Emirates, Canada, Angola, Argentina, Austria, Azerbaijan, Pakistan, Peru, Chile, Kuwait, Mexico, Malaysia, Nigeria, Serbia, Singapore, Taiwan, Chile, Venezuela, Ecuador, Netherlands, Brazil, Vietnam, South Africa, Nigeria, Mexico, Turkey, Hungary, Algeria, Belarus, Belgium, Bhutan, Bolivia, Bulgaria, Croatia, Czech Republic, Estonia, Finland, Greece, Italy, Japan, Libya, Colombia, Ghana, Iran, Denmark, Poland, Australia, Afghanistan, Bahrain, Costa Rica, Egypt, Iraq, Jordan, South Korea, Kazakhstan, Sri Lanka, Lithuania, Norway, Oman, Philippines, Poland, Qatar, Spain, France, United Kingdom, Indonesia, Israel, Iran, Russia, Romania, Thailand, Trinidad & Tobago,Tunisia, Ukraine, Yemen, Hong Kong, Gabon, China, Portugal, Switzerland, New Zealand, Sweden, Slovakia, Kenya, Lebanon, Morocco, Mongolia

Cities We Deliver to

Ubique Alloys Pvt. Ltd. manufactures and exports to multiple cities such as Mumbai, Thane, Navi Mumbai, Pune, Pimpri-Chinchwad, Vadodara, Kolkata, Gurgaon, Ahmedabad, Seoul, Hyderabad, Singapore, Abu Dhabi, Tehran, Calgary, Noida, Riyadh, London, Coimbatore, Jakarta, Istanbul, Bangkok, Kuwait City, Sharjah, Muscat, Edmonton, Busan, Mexico City, Doha, New Delhi, Bengaluru, Chennai, Surat, Bhopal, Ulsan, Faridabad, Houston, Dubai, Jeddah, Aberdeen, Cairo, Geoje-si, Perth, Santiago, Chandigarh, Indore, Kuala Lumpur, Rio de Janeiro, Dammam, Melbourne, Madrid, La Victoria, Bogota, Lahore, Los Angeles, Algiers, Chiyoda, Ankara, Ho Chi Minh City, Toronto, Hong Kong, Howrah, Sydney, Ahvaz, Karachi, Rajkot, Brisbane, Petaling Jaya, Ernakulam, Secunderabad, Gimhae-si, Al Jubail, Port-of-Spain, Thiruvananthapuram, Milan, Atyrau, Lagos, Hanoi, New York, Caracas, Vung Tau, Al Khobar, Manama, Montreal, Granada, Courbevoie, Visakhapatnam, Ludhiana, Moscow, Dallas, Haryana, Colombo